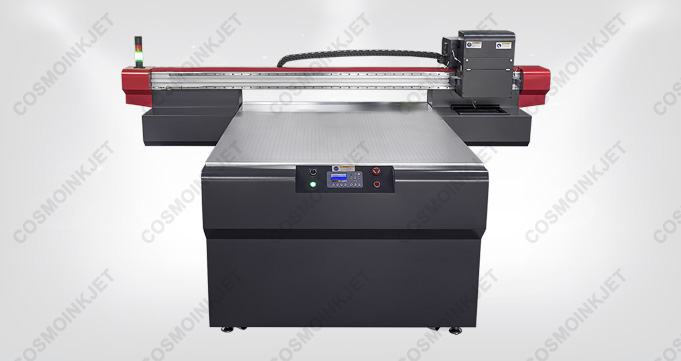

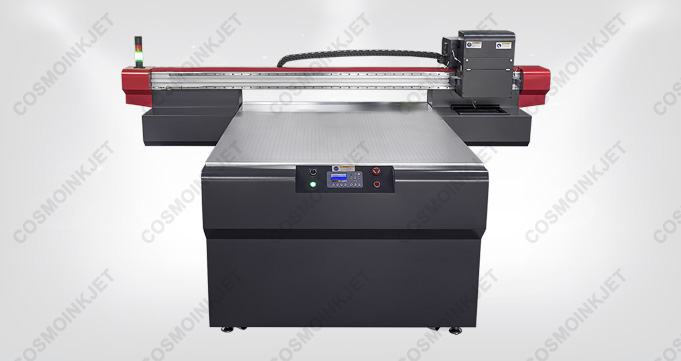

The CG1313 printer is a high-performance UV-LED flatbed inkjet print system with moving gantry. Thanks to the flatbed architecture and UV-LED curing technology, the CG1313 printer owns the ability to print on various sheets, boards, or objects up to 100mm (3.94 ") thick. The CG1313 printer will give you competitive advantages and help you grow your business.

CG1313

CG1313 CG1313

CG1313 CG1313

CG1313 CG1313

CG1313

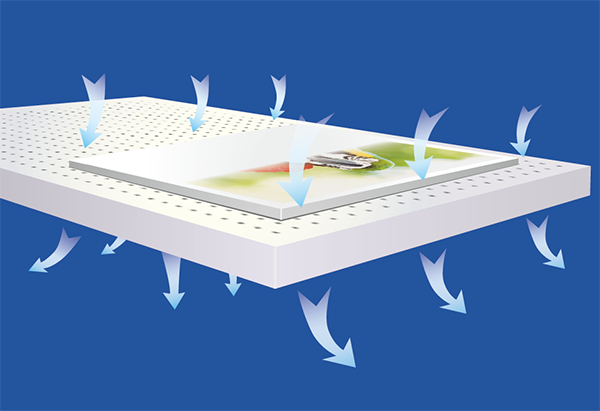

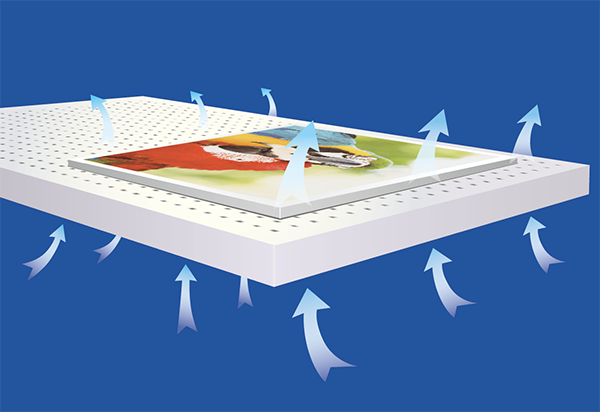

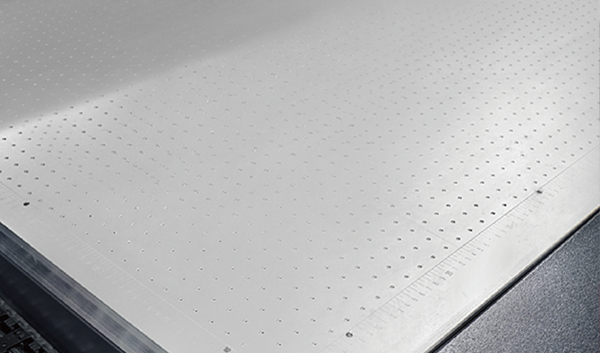

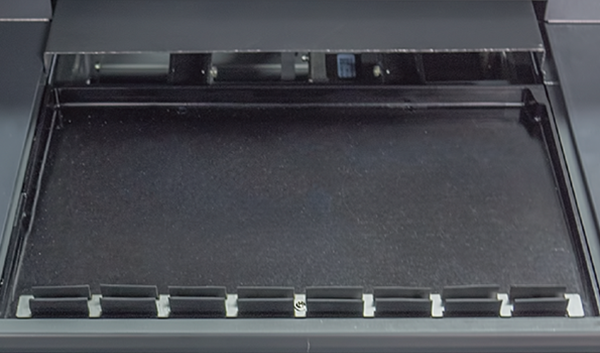

Substrates can be attached firmly to the flatbed table surface by CG1313's vacuum system, ensuring accurate and reliable dot placement even at bi-direction or multi-pass printing mode. The flatbed table is divided into 2 separately controllable table zones, so that you can use only one part of the table for small-sized substrates to maintain powerful vacuum. The blow function achieves lifting of large, thick, or heavy substrates after printing so that you can take the printed substrates away from the flatbed table easily and quickly.

|

|

| Printing | After printing |

The print origin can be precisely and freely set by means of the PCS software. The flatbed table with four scales on the borders shows the accurate size of the substrates and helps you position substrates. Manual substrate registration pins ensure quick, repeatable, and easy loading of rigid substrates in expected register every time, especially for high-accuracy printing, such as double-sided printing, edge-to-edge printing, and template printing.

|

|

| Front Printing | Back Printing |

|

Double-sided Printing helps to realize your creative ideas |

|

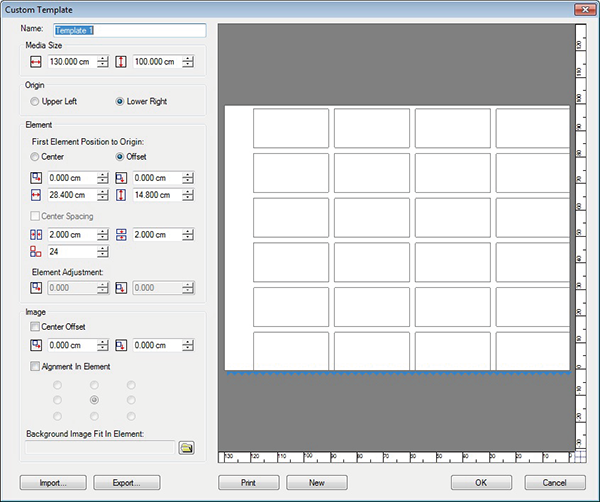

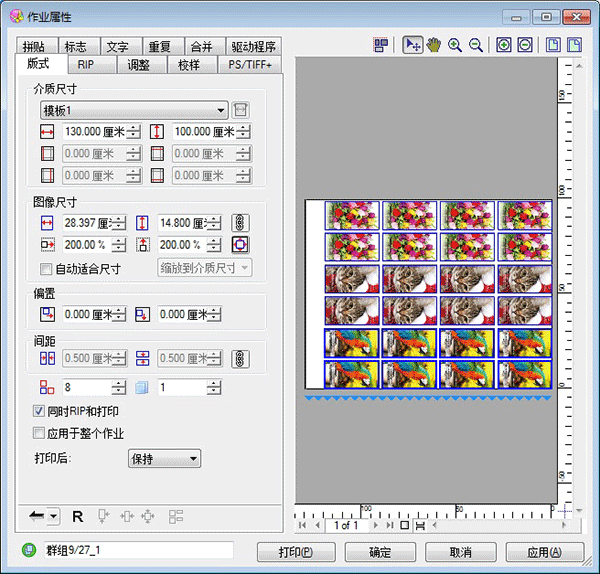

The CG1313 printer is an ideal solution for printing same or different images on a large number of small-sized substrates. Template can be placed on the flatbed table to quickly position small-sized substrates. The ColorPRINT RIP software allows you to customize "template" according to the size of your real template and define the print quantity of each image. The real-time preview makes sure what you see is what you print.

|

|

| Custom Template | Job Properties - Layout |

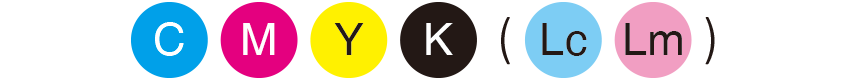

6 color inks including light color inks well reproduce smooth gradations and light tones. 6 color inks including light color inks well reproduce smooth gradations and light tones.

|

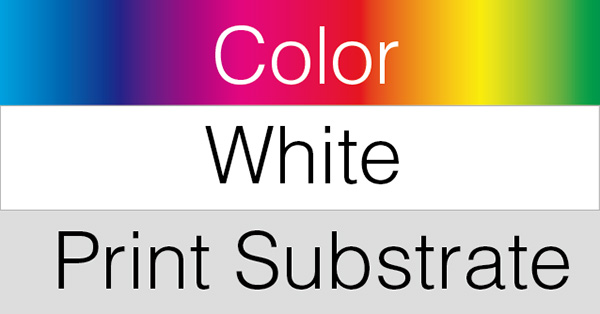

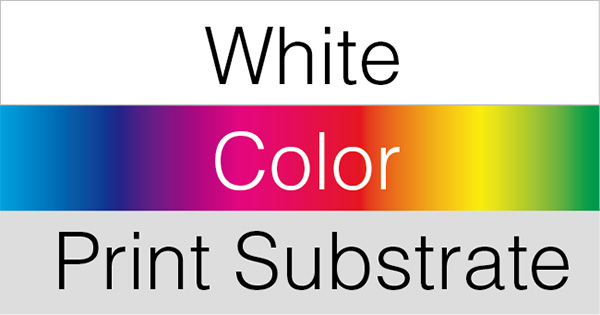

Due to white ink layer under or above the printed image, brilliant and vivid image colors are presented on transparent or colored substrates. Due to white ink layer under or above the printed image, brilliant and vivid image colors are presented on transparent or colored substrates.

|

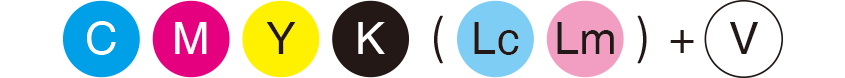

Primer can be printed with CMYK/ CMYKLcLm inks in one run and offers better ink adhesion on different materials. Primer can be printed with CMYK/ CMYKLcLm inks in one run and offers better ink adhesion on different materials.

|

Printed with CMYK/ CMYKLcLm inks in one run, varnish makes prints more eye-catching. Printed with CMYK/ CMYKLcLm inks in one run, varnish makes prints more eye-catching.

|

White ink and varnish can be printed with CMYK/ CMYKLcLm inks for a wide variety of applications. White ink and varnish can be printed with CMYK/ CMYKLcLm inks for a wide variety of applications.

|

The CG1313 printer enables over-printing for backlit applications on transparent materials, under-printing for colored materials, white ink printing out of images, or printing white as a spot color.

The separate white ink circulation system easily keeps white ink well mixed for consistent and reliable printing. High quality images without white stitch lines can be obtained thanks to the Choke feature in the ColorPRINT RIP software.

| Under-Printing | Over-Printing | |

| Print white ink at the area of job |

|

|

| Print white ink at the area of image |

|

|

| Print white ink and color inks individually |

|

|

Active Negative Pressure System ensures high-quality printing at higher firing frequency of industrial high-speed print heads. |

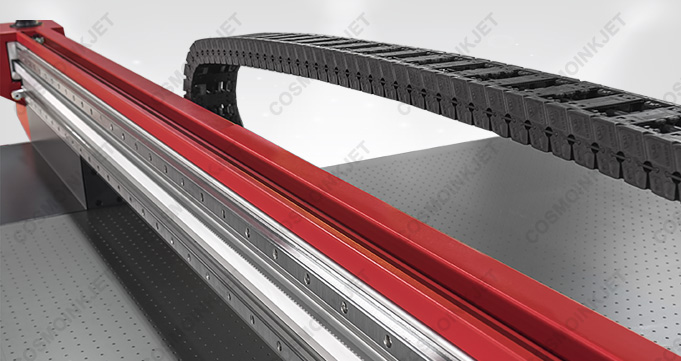

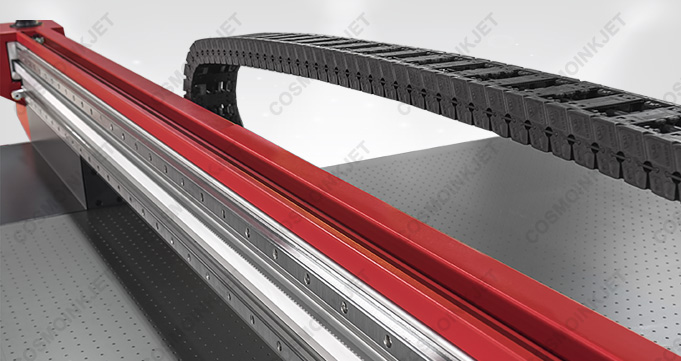

The Lead Screw with linear guide and servo motor realizes precise motion control of the printing gantry, which improves print quality significantly. |

The Multi-point Adjustment System of CG1313 assures the excellent flatness of the flatbed table, so that droplets are placed on the substrates where intended over the entire flatbed table. |

Based on an all-in-one design concept, the small and compact Print Head Maintenance Module allows automatic purging, wiping and capping for convenient unattended operation, ensuring consistent nozzle performance. |

The Stable Beam with two linear guides, magnetic scale, and servo motor guarantees accurate movement and accurate positioning of the print head carriage. |

User friendly color LCD Smart Panel provides printer status information and offline printer control. |

| CG1313 | ||

| Print Head Model | MH5420 | |

| Number of Heads | 6 | 7 |

| Colors | CMYKLcLm | CMYKLcLm + W |

| Resolution | 1200 × 600dpi | |

|

Productivity Unit: m²/ hr. (ft²/ hr.) |

14.9 (159.3) | 14.3 (153.9) |