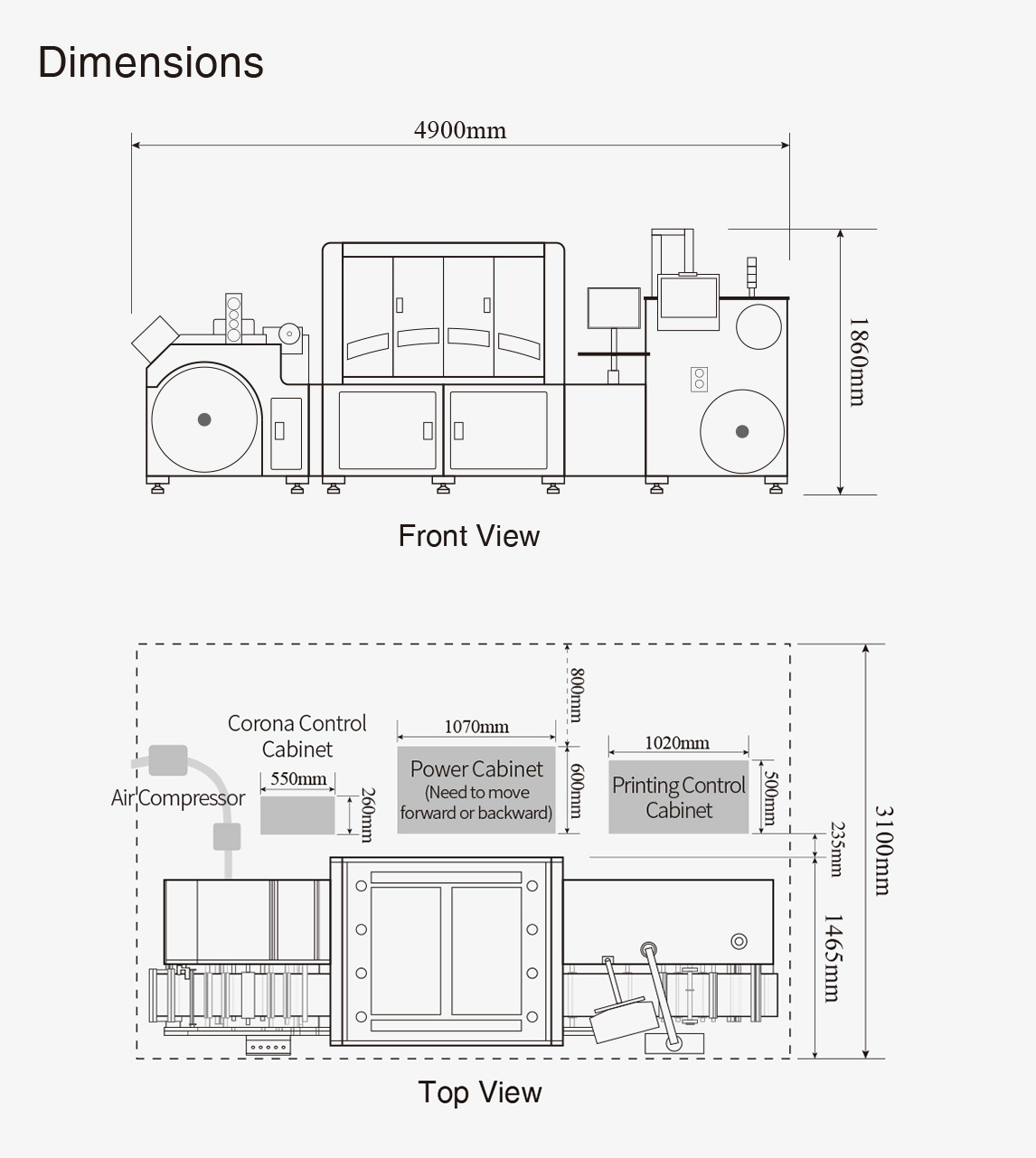

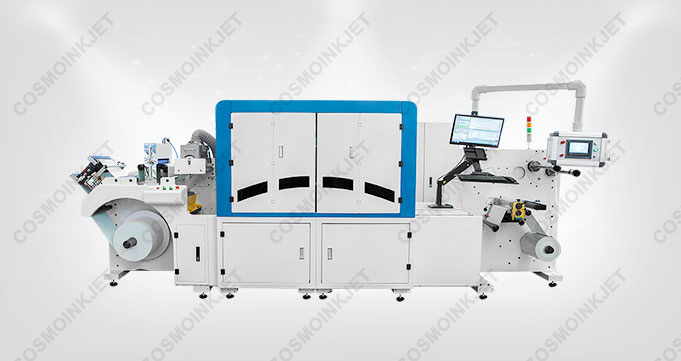

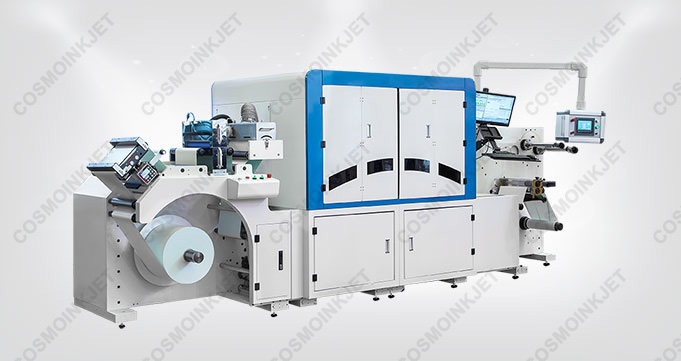

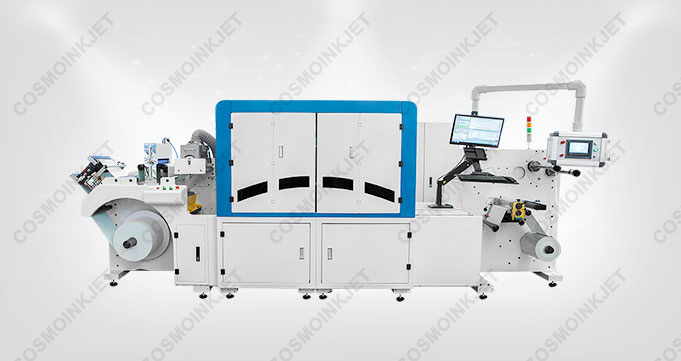

Gemini 330 is Cosmoinkjet's newly-developed full

color UV label press for label and packaging

industries. Integrated with advanced UV inkjet

printing technology, Gemini 330 is designed with

superior grade components available in the market

today. Thanks to its 6 ink channels in addition to

the proven technologies of color management and

VDS (Variable Droplet Size) control, Gemini 330

enables you to easily obtain vibrant print quality

labels for short- & medium-run jobs.

Gemini 330 works with MagicPage VDP software

and supports printing variable data, including

barcodes, serial numbers, dates, time, texts,

logos and images.

Owing to the completely modular design,

Gemini 330 offers the flexibility of adding options,

such as cold foil, lamination, laser die-cutting

or slitting, to meet your demands in the future.

Gemini 330 will be an ideal choice for those who

are looking for industrial digital label and

packaging printing solutions.

Gemini 330

Gemini 330 Gemini 330

Gemini 330 Gemini 330

Gemini 330 Gemini 330

Gemini 330

Industrial high-resolution and high-speed DOD piezoelectric print heads combine excellent print quality and high efficiency with exquisite and consistent color reproduction, plus sharp, clear, easy-to-read barcodes, graphics, and texts. Gemini 330 prints texts small to 3pt and barcodes with crisp edges.

Gemini 330 enables you to print CMYK with varnish ink to provide a variety of surface finishes. The overall label can be covered with a gloss or matte finish; or glossy or matte spot varnish can be added to some specified appealing parts.

The white ink printing option including under-printing and over-printing offers solid and opaque white ink layers on transparent films for “no-label look” labels, as well as metallic substrates frequently used in the cosmetic or medical markets. High quality images without white stitch lines can be obtained thanks to the Choke feature in the ColorPRINT RIP software.

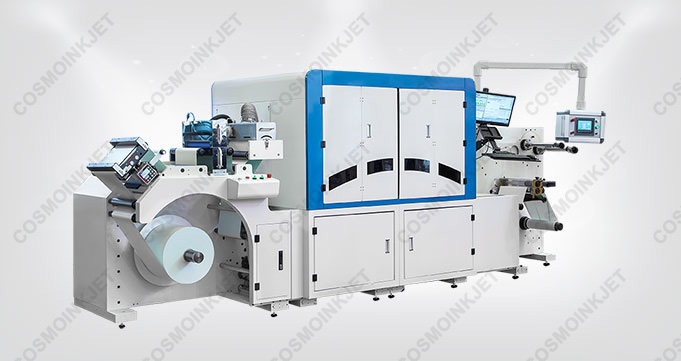

Arc Tension Controldelivers accurate tension control and better droplet placement. |

UV-LED Pinning Curing“freezes” ink droplets to control dot gain before overlaying follow-up colors or doing a full curing. |

Print Head Cleaning Moduleallows full automatic purging, wiping, and capping for convenient unattended operation. |

Unwinderis equipped with electronic web guiding system for high accuracy feeding, and a 76.2mm (3") servo-driven unwind spindle with magnetic particle clutch. |

Rewinderutilizes a 76.2mm (3") servo-driven rewind spindle with magnetic particle clutch and closed-loop tension control system, supporting rewind diameter up to 700mm (27.6"). |

Printing Control Cabinet integrates Automatic Ink Supply System, Active Negative Pressure System, and other features; 10L ink tanks are designed for high volume production. |

Movable Touch Screen offers user-friendly operation with high efficiency and flexibility. |

Corona Treatment System effectively pretreats the surface of substrates to increase the adhesion of inks. |

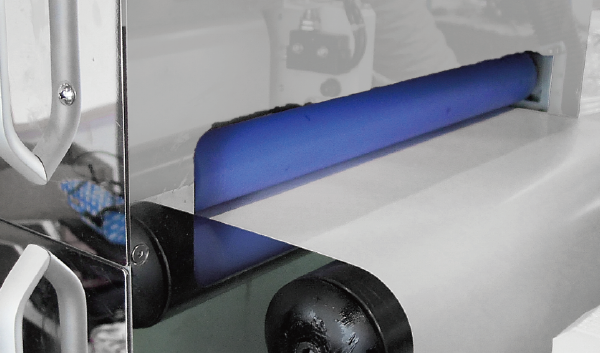

Web Cleaner ensures no material waste, no down time and stable printing by effectively removing dust including paper particles, powders and other visible particles. |