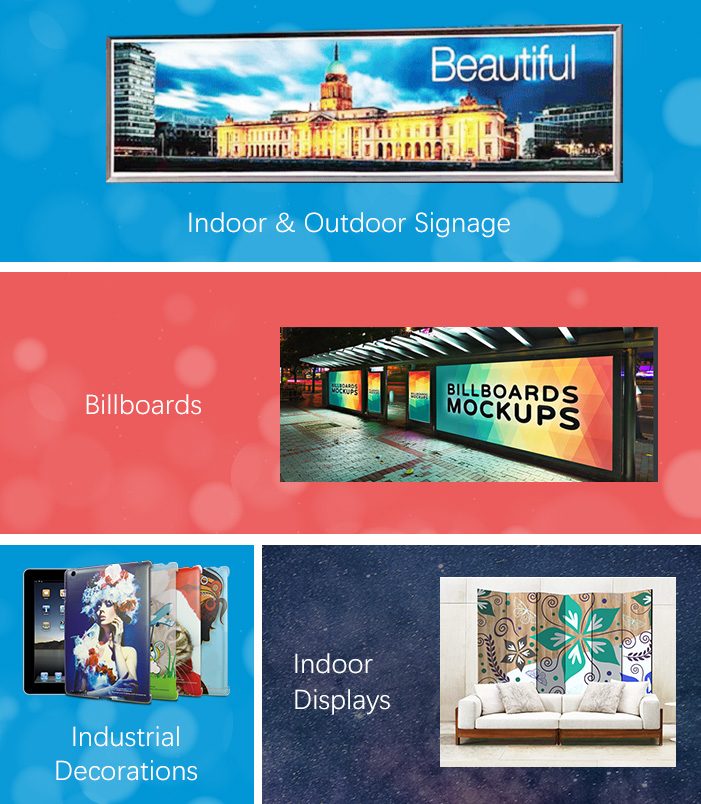

With the movable printing gantry design, the FG2512 flatbed inkjet printer step moves the gantry and stays the printing platen stationary when printing.

FG2512

FG2512 FG2512

FG2512 FG2512

FG2512 FG2512

FG2512

FG2512 printer utilizes the advanced print heads. Print heads feature up to 600dpi physical resolution, minimum 5pl droplet and high jetting frequency. One print head can print two colors.

Proprietary VDS (Variable Droplet Size) control technology integrates print head control of 3-level droplet sizes with ColorPRINT RIP Software for producing sharper images with smoother gradients.

|

| Variable Droplet Size Control Technology |

Proprietary image algorithm enables you to print large-size images reliably without stopping.

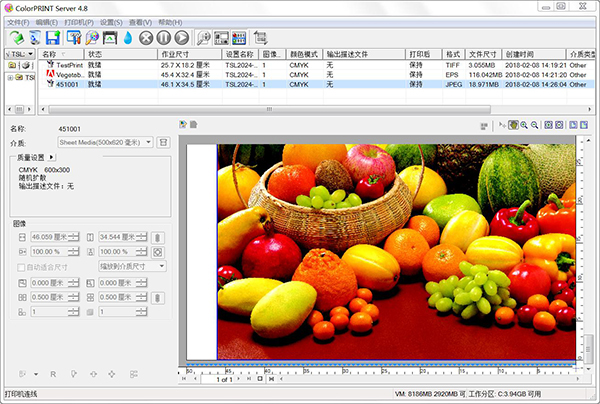

Working seamlessly with the professional ColorPRINT RIP Software, FG2512 printer produces vivid colors and fine details with ColorPRINT's enhanced color management and raster image process technology to grab viewers' attention.

|

|

|

ColorPRINT RIP Software |

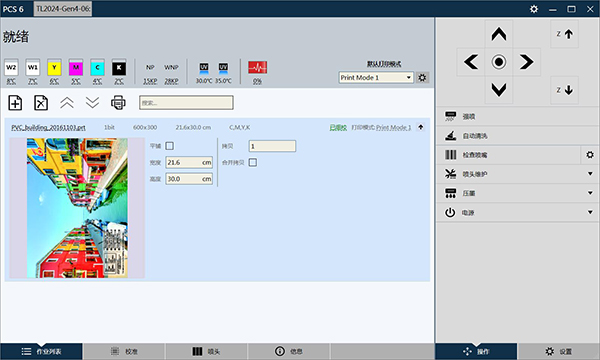

Printer Control Software (PCS) |

6 color inks including light color inks well reprint smooth gradations and light tones. 6 color inks including light color inks well reprint smooth gradations and light tones.

|

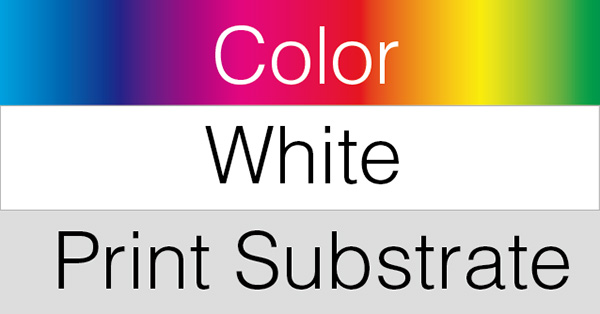

Directly prints on transparent and colored substrates. Brilliant and vivid image colors are displayed due to white ink layer under the image. Directly prints on transparent and colored substrates. Brilliant and vivid image colors are displayed due to white ink layer under the image.

|

The primer can be printed with CMYK inks simultaneously. The automatic primer application function enables the primer to be applied in the print image area for better adhesion on different materials. The primer can be printed with CMYK inks simultaneously. The automatic primer application function enables the primer to be applied in the print image area for better adhesion on different materials.

|

The varnish can be printed with CMYK inks simultaneously. Images will look more attractive by printing the varnish layer. The varnish can be printed with CMYK inks simultaneously. Images will look more attractive by printing the varnish layer.

|

The white ink and varnish can be printed with CMYK inks for special market applications. The white ink and varnish can be printed with CMYK inks for special market applications.

|

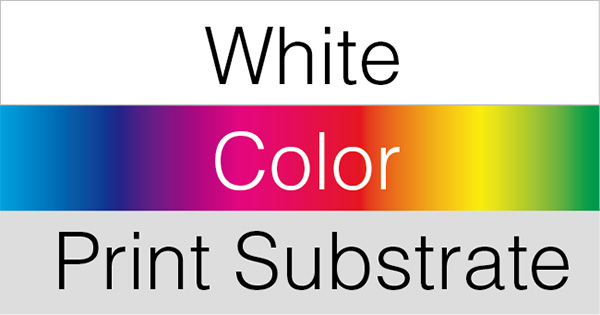

Printing with high density white ink, FG2512 offers bright and vivid colors on transparent or colored media. Thanks to the separate white ink circulation system, FG2512 easily keeps white ink well mixed for consistent and reliable printing.

Coming with the professional ColorPRINT RIP software, FG2512 enables over-printing for backlit applications on transparent materials, under-printing for colored materials, printing white out of images, and printing white as a spot color.

| Under-Printing | Over-Printing | |

| Print white ink at the area of job |

|

|

| Print white ink at the area of image |

|

|

| Print white ink and color inks individually |

|

|

With the help of a microprocessor, the Active Negative Pressure System ensures high-speed and high-quality printing when print heads jet at higher firing frequency. |

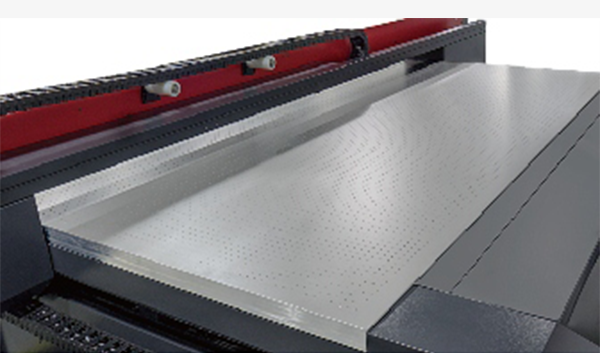

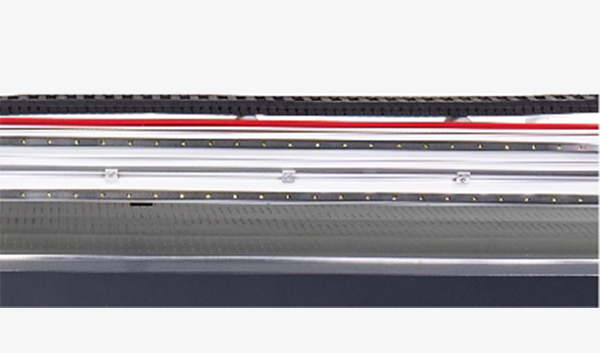

The six-zoned vacuum table keeps media stationary with one, two,… or six vacuum systems, ensuring accurate color registration even at bi-direction or multi-pass printing. |

Dual-origin mode enables to automatically calibrate parallelism of the guide beam in case of deviation, ensuring precise printing. |

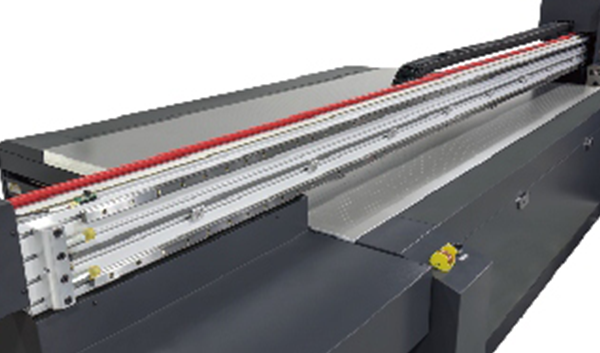

Dual linear guides ensure smooth carriage moving to achieve accurate printing. |

Dual lead screws and servo motors realize precise motion control of the printing gantry, which improves print quality significantly. |

The double-inlet bulk ink tanks with liquid level sensors are easily used for adding ink and alarming for the shortage of ink. |

| Print Head Model | ||

| Number of Print Heads | ||

| Colors | ||

| Print Resolution | ||

|

Productivity

Unit: m²/ hr. (ft²/ hr.) |

Production Mode |

4 Pass |

|

4 Pass+ |

||

| Standard Mode |

6 Pass |

|

|

6 Pass+ |

||

| Quality Mode |

8 Pass |

|

|

8 Pass+ |

||

| MH2420 | ||

| 4 Colors or 6 Colors, 16 Heads or 24 Heads | ||

|

CMYK, CMYKLcLm |

||

| 1200 × 600dpi | ||

| 96 (1033) | ||

| 78 (840) | ||

| 63 (678) | ||

| 55 (592) | ||

| 47 (506) | ||

| 42 (452) | ||

| MH5420 | ||

| 3 Groups, 0.5×3×4 Colors or 6 Colors, 6 Heads or 9 Heads | ||

|

CMYK, CMYKLcLm |

||

| 1200 × 600dpi | ||

| - | ||

| 74 (796) | ||

| - | ||

| 56 (603) | ||

| 42 (452) | ||

| - | ||

| Kyocera KJ4 | ||

| 8 Colors, 4 Heads | ||

|

CMYK × 2 CMYKLcLmOrGr CMYKLcLmRB CMYKLcLmRG CMYKOrGrRB |

||

| 1200 × 600dpi | ||

| 60 (646) | ||

| 43 (463) | ||

| 40 (431) | ||

| 34 (366) | ||

| 33 (355) | ||

| 28 (301) | ||